Irata

IRATA – Industrial Rope Access Trade Association (Międzynarodowe Branżowe Stowarzyszenie Przemysłowego Dostępu Linowego). Pomysł zorganizowania takiego stowarzyszenia w Wielkiej Brytanii powstał pod koniec lat 80. z inicjatywy kilku osób i przedsiębiorstw zaangażowanych w wykorzystywanie technik dostępu linowego do celów przemysłowych. IRATA opracowała procedury bezpieczeństwa związane z wykonywaną pracą na wysokości oraz system szkolenia i oceny specjalistów dostępu linowego. System ten jest uznawany obecnie za najlepszy na świecie i powszechnie akceptowany.

Opracowując swój system IRATA obrała nadrzędne cele takie jak:

- Poprawa bezpieczeństwa w przemyśle wykorzystującym prace z zakresu dostępu linowego.

- Stworzenie zestawu norm i standardów oraz wymagań i wskazówek dotyczących szkolenia w zakresie alpinizmu przemysłowego.

- Stworzenie systemu odpowiedniej oceny oraz rejestracji techników.

Dzięki rygorystycznemu przestrzeganiu wszystkich zasad obowiązujących w systemie IRATA nie odnotowano do tej pory żadnego wypadku śmiertelnego.

10 głównych zasad bezpiecznego dostępu linowego w standardzie IRATA

- System podwójnych lin ,wszystkie operacje muszą być wykonywane przy użyciu dwóch urządzeń asekuracyjnych: roboczego i asekuracyjnego.

- Urządzenie asekuracyjne umiejscowione wysoko.

- Nadzór dostosowany do umiejętności pracownika, wykonywanego zadania i warunków atmosferycznych.

- Zachowany stały kontakt wzrokowo-głosowy pomiędzy pracownikami.

- Ocena ryzyka i procedury ratownicze dostosowane do okoliczności i przekazane wszystkim pracownikom.

- Codzienne szkolenie stanowiskowe, zrealizowane i zarejestrowane.

- Wcześniejsze przygotowanie miejsca pracy i planowanie czynności, znajomość metod ratowniczych i ewentualne próby praktyczne.

- Sprzęt ratowniczy łatwo dostępny w razie potrzeby.

- Odpowiednio wyszkoleni i wykwalifikowani pracownicy, znający zasady pierwszej pomocy.

- Możliwość identyfikacji i codzienne sprawdzanie sprzętu przed zastosowaniem.

Terminarz IRATA - Kraków 2024

Terminarz IRATA - Poznań 2024

Jesteśmy tutaj, aby Ci pomóc. Nasz zespół ekspertów jest zawsze gotowy, aby odpowiedzieć na Twoje pytania i wsparcie na każdym etapie Twojej przygody z kursami IRATA. Czy masz wątpliwości odnośnie wyboru odpowiedniego poziomu kursu czy szczegółów szkolenia? Prosimy, wypełnij obok formularz, a my odpowiemy tak szybko, jak to tylko możliwe. Twoje sukcesy są dla nas ważne, dlatego jesteśmy dostępni, aby pomóc Ci we wszystkim, co potrzebujesz. Zawsze możesz na nas liczyć!

IRATA

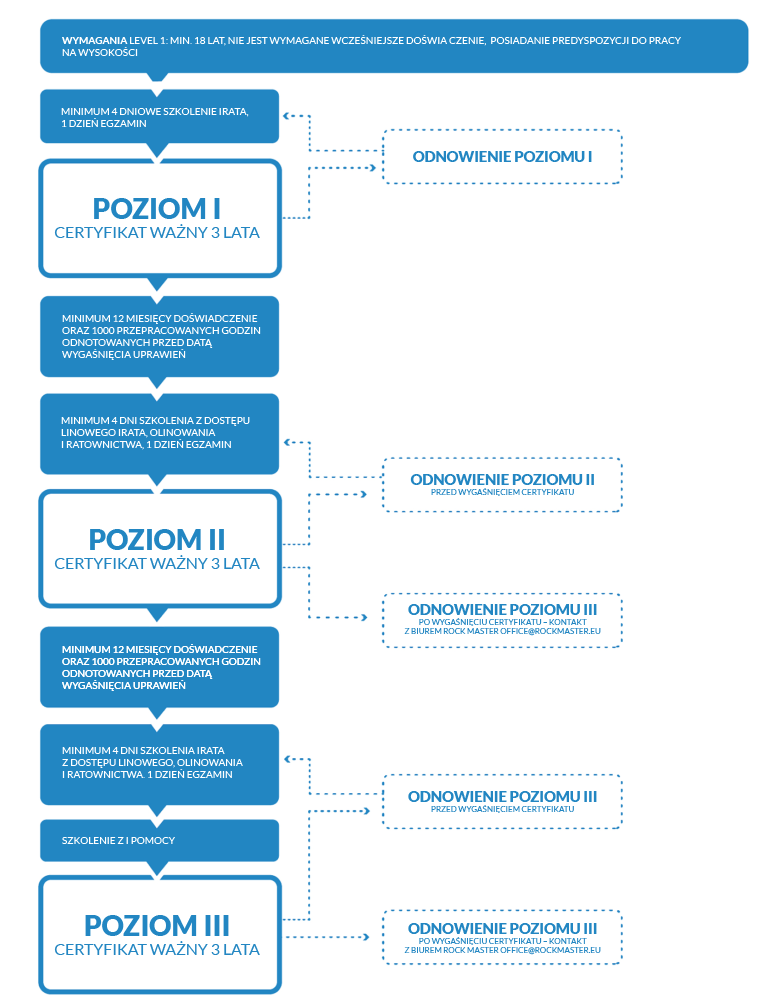

IRATA opracowała oficjalny schemat szkolenia oraz strukturę podziału na poziomy, w której to pracownicy zostali podzieleni na trzy stopnie zależne od ich doświadczenia i umiejętności.

- Level 1 (Poziom 1): technik – stażysta

- Level 2 (Poziom 2): technik

- Level 3 (Poziom 3): technik nadzorujący

Podstawowe umiejętności na określonych poziomach

Level 1: Technik na tym poziomie jest zdolny do wykonania działań dostępu linowego w ograniczonym zakresie pod nadzorem osoby z kwalifikacjami poziomu 3. Jest także odpowiedzialny za przeglądy własnych środków ochrony indywidualnej.

Level 2: Technik na tym poziomie posiada wiedzę oraz umiejętności w pełnym zakresie dostępu linowego, bierze udział w akcjach ratowniczych, transportowych i innych, lecz pod nadzorem technika na poziomie 3.

Level 3: Technik nadzorujący bierze pełna odpowiedzialność za dane projekty oraz grupy podlegających mu techników. Prezentuje pełną wiedzę oraz umiejętności z poziomów 1 i 2. Posiada kompleksową wiedzę na temat zaawansowanych technik ratowniczych, przepisów prawnych i systemu certyfikacji IRATA.

Certyfikaty

Zaliczenie każdego z opisanych poziomów szkolenia IRATA skutkuje otrzymaniem odpowiedniego certyfikatu, oraz dziennika pracy (tzw. Logbook) , w którym należy odnotowywać przebieg całej pracy zawodowej danego technika, jego wszelkie dodatkowe, zaświadczenia i certyfikaty podnoszenia kwalifikacji.

Certyfikaty IRATA są ważne przez okres 3 lat.

Szkolenie odnawiające

Po upływie trzech lat, ale przed datą wygaśnięcia uprawnień, w celu wykonywania dalszej pracy technika dostępu linowego należy odnowić uprawnienia. Następuje to poprzez 4 dniowe szkolenie odnawiające na odpowiednim poziomie oraz niezależną ponowną ocenę akredytowanego przez IRATA asesora (1 dzień).

Szkolenie dodatkowe (utrwalające wiedzę)

Szkolenie dodatkowe jest to szkolenie przypominające zdobyte umiejętności na każdym poziomie zaawansowania. Czas trwania szkolenia oraz ćwiczenia ustalane są indywidualnie (może być wymagane powtórzenie pełnego kursu i egzaminu u niezależnego asesora).

Takie szkolenie muszą przejść technicy, którzy nie brali udziału w pracach na wysokości przez okres 6 miesięcy lub dłuższy oraz pracują nieregularnie.

Od 01.01.2020 IRATA wycofała możliwość bezpośredniego przystąpienia do szkolenia Direct Entry.

Wymagania dla kandydatów

- Kandydaci muszą mieć ukończone 18 lat.

- Kandydaci muszą być sprawni fizycznie, a także nie mogą wykazywać, żadnych warunków, które mogłyby uniemożliwiać bezpieczną pracę.

- Powinni być pewni, że posiadają adekwatny do tej pracy poziom sprawności fizycznej oraz wytrzymałości fizycznej i psychicznej. Ponadto kandydat taki musi umieć dobrze znosić różne warunki atmosferyczne jak zimno, upał czy wiatr.

- Kandydat musi być odpowiedzialny, rzetelny i wiarygodny.

- Brak przeciwwskazań do pracy na wysokości, takich jak:

- choroby serca/bóle w klatce piersiowej;

- wysokie ciśnienie krwi;

- epilepsja, omdlenia;

- lęk wysokości, zawroty głowy;

- zaburzenia równowagi;

- uszkodzenia funkcji kończyn;

- uzależnienie alkoholowe lub uzależnienie od środków odurzających;

- zaburzenia i choroby psychiczne;

- cukrzyca.

Przebieg szkolenia

Szkolenie na każdym poziomie trwa 4 dni (poza szkoleniem dodatkowym, którego długość trwania ustalana jest indywidualnie). W tym czasie odbywają się wykłady teoretyczne obejmujące zapoznanie techników ze sprzętem i z wiedzą na temat metod dostępu linowego, a także odpowiednimi przepisami prawnymi. Główną częścią jest jednak szkolenie praktyczne pozwalające kursantom na zapoznanie się z odpowiednimi technikami. Szkolenie kończy się egzaminem teoretycznym oraz praktycznym, który przeprowadzany przez niezależnego, akredytowanego przez IRATA egzaminatora – asesora i trwa cały dzień.

Dofinansowanie

Jeśli chcesz zdobyć międzynarodowe uprawnienia do pracy na wysokości IRATA skorzystaj z oferty szkoleń współfinansowanych ze środków Unii Europejskiej.